|

Try walking into a Home Depot carrying a propeller and see what kind of day you have. Parts from the Propeller Shipping Materials at your local Plumbing Supply. What was wanted was a reusable, strong and easy to make container to ship a propeller securely. This version used Schedule 35 Sewer Pipe - 6 inches diameter for the main casing. This was cut 2 inches longer than the propeller. The end caps are made from 6 inch PVC adapters and 6 inch clean out caps. The propeller is held in place with two 3/4 inch plywood discs that are secured in the tube with slots for the prop to fit into.

|

|

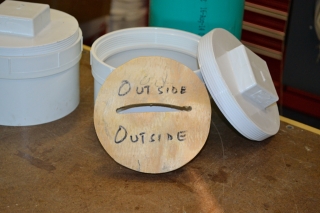

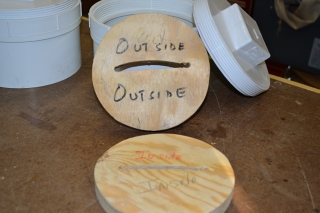

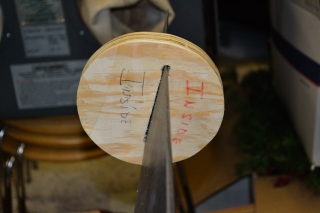

The blade discs were made from 3/4 inch plywood scrap. They measure 5 and 15/16 inches in diameter and fit nicely into the main tube. The blade slots were cut by drilling two 1/4 inch holes at each end of the blade and then a jig saw used to cut the profile. It was desired to support the blade from the 8 inch mark from the end of each blade. They were marked for reference (inside/outside) and then one was secured with 3 screws through the main pipe in countersunk holes with 1 inch dry wall screws.

|

|

Two discs were made to support weach end of the blade approximately 7.5 inches from the tip. The center was supported vias the close tolerance fit of the internal diameter of the SCH35 6-inch Sewer pipe and the 1A105 propeller hub.

|

|

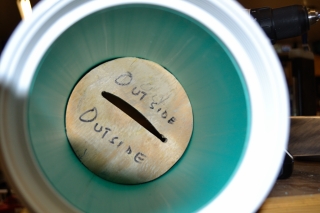

Wood spacer disc installed on the blade. This in turn is inserted into the main shipping tube and positioned for drilled to secure the disc into place.

|

|

Once the spacer is in the main tube in position on the blade, then it is drilled into the thickest wood part of the disc (to protect the blade metal) with 1 inch dry wall screws. 3 screws are used on the bottom disc since this one will not be removed to gain access to the propeller after shipping.

|

|

Here is the final product with the end caps glued on and both spacer secured. The clean out plugs are secured to the main body with 3/8 yellow nylon line.

|

|

This shows the logbook in a ziploc bag secured in the end between padding.

10 foot section SCH35 6-inch Sewer pipe - $21.94

2 Adapters - $25.77

2 Clean out caps - $13.94

PVC Cleaner 8 oz - $4.71

PVC Cemet 8 oz - $6.12

|

|

1 and 1/2 inch Styrofoam insulation was used as padding to protect the blade tips and hold the logbook during transit.

|

|

Finally, lanyards were made to secure the caps to the main body with A 12 inch piece of 3/8 nylon line on each end. Holes were drilled with a small step bit and then a knot was tied on each end of the rope after feeding it through the hole. It was further secured with burning with a lighter to fix the knot. This way the lanyards also serve as secure handles on each end.

|

Tools Needed

Jig Saw for cutting wood and pvc - variable speed a plus

Drill and various bits (1/4 in, step, 1/2-inch for counter sink

Sandpaper

PVC Cleaner & Cement

Ruler & Pencil

|

Time Required:

~ 2 hours

|

Alternative Construction

Instead of using wooden discs to secure the prop, you could take a 5 7/8 hole saw and cut lots of 1.5 inch styro disc (you could use cheaper white instead of dense pink) and then just stick them on the prop and slide the whole affair into the tube.

This was for a 1A105 series McCauley prop for a two-seater. For the larger props needed for the 4-seaters (and the 1C) then you could step up to the next size of PVC (8-inch) and start there. There would even be room for the spacer. Enjoy!

|

|