The Page of Much Badness for a Nose Fork

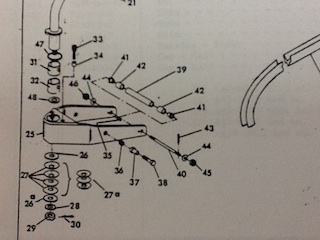

The nose fork assembly on our planes is very clever and needs to be assembled in the precise order. Please see the figure from the Parts Manual for the stacking of all components.When you put the wrong number of thrust bearings in the fork socket it will cause problems. There is supposed to be one thrust bearing (bronze in color) in the bottom of the socket. If you have it installed on the outside of the fork bottom, then you crush the o-ring at the top which prevents it from keeping water out of the socket. Likewise, if you put in too many, one regular and one thin in the socket, then the o-ring does not match properly and water can flow in.

The thin thrust bearing(s) might be needed on the bottom of the fork for proper bellville washer tension and good cotter pin capture. Click on an image for a larger view

FIGURE 11. NOSE LANDING GEAR INSTALLATION page 102 Parts Manual |

Parts by Number 47. O-ring (MS29513-224) Same as brake 48. Thrust Bearing (TT-1508-2) 25. Fork Assembly (702067-501 - Code E) 26. Washer (702054-5) 27. Belleville Washer (702054-4) 'cup shaped (3/4)' 26. Washer (702054-5) 28. Washer (AN960-1016L) (AR) 29. Nut (AN320-10) use a1-inch socket 30. Cotter Pin (MS24665-353) |

O-Ring Crushed with No Thrust Bearing |

|

Crushed O-ring caused by no thrust bearing in the fork socket |

Also note the condition of the strut spindle. Allowing water to get in for years corroded the spindle and a new/serviceable strut will be required. To help in this area it is important to get a good nose strut seal with the 'Nose Fairing Top Seal' (W224). See Perfect Nose Seal |

Multiple Thrust Bearings |

Ugly Ugly Parts |

The Rest of the 'Nasty Bits' |

Strut Spindle |

Fork Socket |

Nose Gear as Removed |

Nose Wheel Bearing Cup |